Top 10 Print Production Methods for Decor

Decorating interiors is an art form that has been revolutionized by various print production methods. These techniques have allowed for vast creativity and personalization when it comes to wall art, home accessories, and more. Here’s a look at the ten most popular print production methods embraced by interior design enthusiasts and the general public alike.

1. Digital Printing

Digital printing has become extremely popular for decor prints due to its versatility and efficiency. It allows for high-quality prints with vibrant colors, perfect for images and detailed designs.

2. Screen Printing

Screen printing is a traditional method loved for its handcrafted feel and durability. It’s commonly used for large batches of prints and gives a unique tactile quality to the artwork.

3. Lithography

Lithography is a classic method that’s been around since the 18th century. It offers exceptional color depth and detail, making it ideal for artistic and vintage decor prints.

4. Giclée Printing

Giclée printing is synonymous with high-end art reproductions. The inkjet technique can reproduce the nuances of an original painting, offering exceptional quality for fine art prints.

5. Flexography

Primarily used for wallpapers and packaging, flexography is a modern print method known for its fast production speeds and its ability to print on a variety of materials.

6. Letterpress

The letterpress gives an elegant, debossed effect to prints, creating a timeless look. Its distinct appearance is a favorite for typographic decor and high-end invitations.

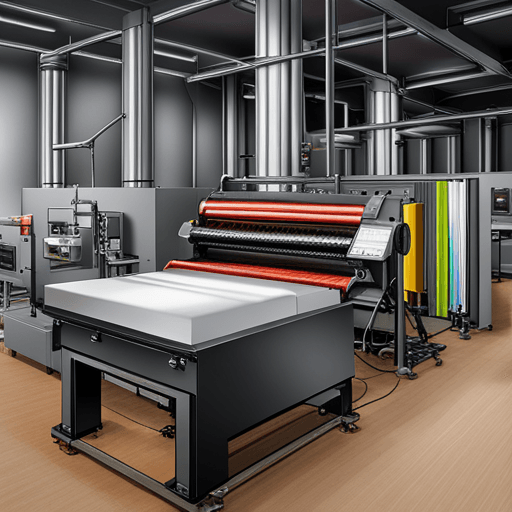

7. Offset Printing

Offset printing is excellent for large volumes and is often used for posters and larger artworks. It provides accurate color reproduction and crisp, clean professional results.

8. Dye Sublimation

Dye sublimation excels at vibrant, permanent prints on fabrics and rigid materials, such as decorative tiles and textiles used for cushions, curtains, and upholstery.

9. Engraving

Engraving lends a sophisticated and luxurious feel to decor elements. It involves etching designs into materials like metal, wood, or glass.

10. Foil Stamping

Foil stamping is used to add shiny, metallic finishes to prints. It’s particularly popular for adding opulent details to artwork, creating a rich and glamorous aesthetic.

Each of these print production methods offers its own unique set of characteristics and appeals, allowing interior design aficionados to choose just the right technique to complement their decor style and personal taste. Whether looking for contemporary, sleek designs or traditional, artisanal qualities, the diversity of printing methods caters to all preferences in home decor.

Understanding the advantages each print production method offers can guide designers and homeowners in making informed choices:

Digital Printing:

- Speed: Digital prints are produced rapidly, making it ideal for tight deadlines.

- Customization: Offers the ability to easily customize each print without significant setup costs.

- Precision: Achieves high-resolution images with sharp details and rich color fidelity.

Screen Printing:

- Durability: Inks used in screen printing are durable and long-lasting, especially on fabric.

- Vibrancy: Produces vibrant colors that are hard to achieve with other techniques.

- Bulk Efficiency: More cost-effective for larger quantities, keeping unit prices lower.

Lithography:

- Quality: Exceptional color depth and detailing that replicates the original artwork.

- Texture: The unique texture of lithographic prints adds an artistic touch.

- Versatility: Suitable for a wide range of printing materials.

Giclée Printing:

- High-End Reproduction: Captures the look and feel of the original art with superb accuracy.

- Longevity: Uses archival-quality inks that resist fading over time.

- Color Range: Wide color gamut allows for smooth gradients and color transitions.

Flexography:

- Speed: Capable of high-speed production runs.

- Material Diversity: Prints on various substrates including plastic, metallic films, and paper.

- Cost-Effective: Lower cost per unit for high-volume orders makes it economically viable.

Letterpress:

- Tactile Finish: Adds an elegant, debossed effect to designs.

- Craft Appeal: Offers a handcrafted quality that conveys premium value.

- Vintage Charm: Particularly appealing for those wishing to evoke a classic or retro feel.

Offset Printing:

- Large Volume Efficiency: Economical for large runs with consistent high quality.

- Color Accuracy: Precisely controls the amount of ink applied, resulting in accurate color reproduction.

- Material Flexibility: Can print on various paper types and weights.

Dye Sublimation:

- Fade-Resistant: Heat transfer ensures the print is less likely to fade or crack.

- Consistency: Produces consistently high-quality images with minimal variation.

- Versatile Fabric Applications: Ideal for decorative purposes requiring print on different materials.

Engraving:

- Elegance: Conveys sophistication and permanence with its indented design.

- Distinctive Touch: Creates a unique tactile experience for intricate artwork.

- Durability: Engraved designs do not wear off easily, ensuring longevity.

Foil Stamping:

- Visual Appeal: Adds a shiny, luxurious effect for distinctive decor.

- Customization: A myriad of foil colors and finishes allows for personalization.

- Branding Elevation: Often used to convey a high-end, premium brand image.

Each method suits different applications and visions, empowering creators to match the production technique with the desired outcome for the