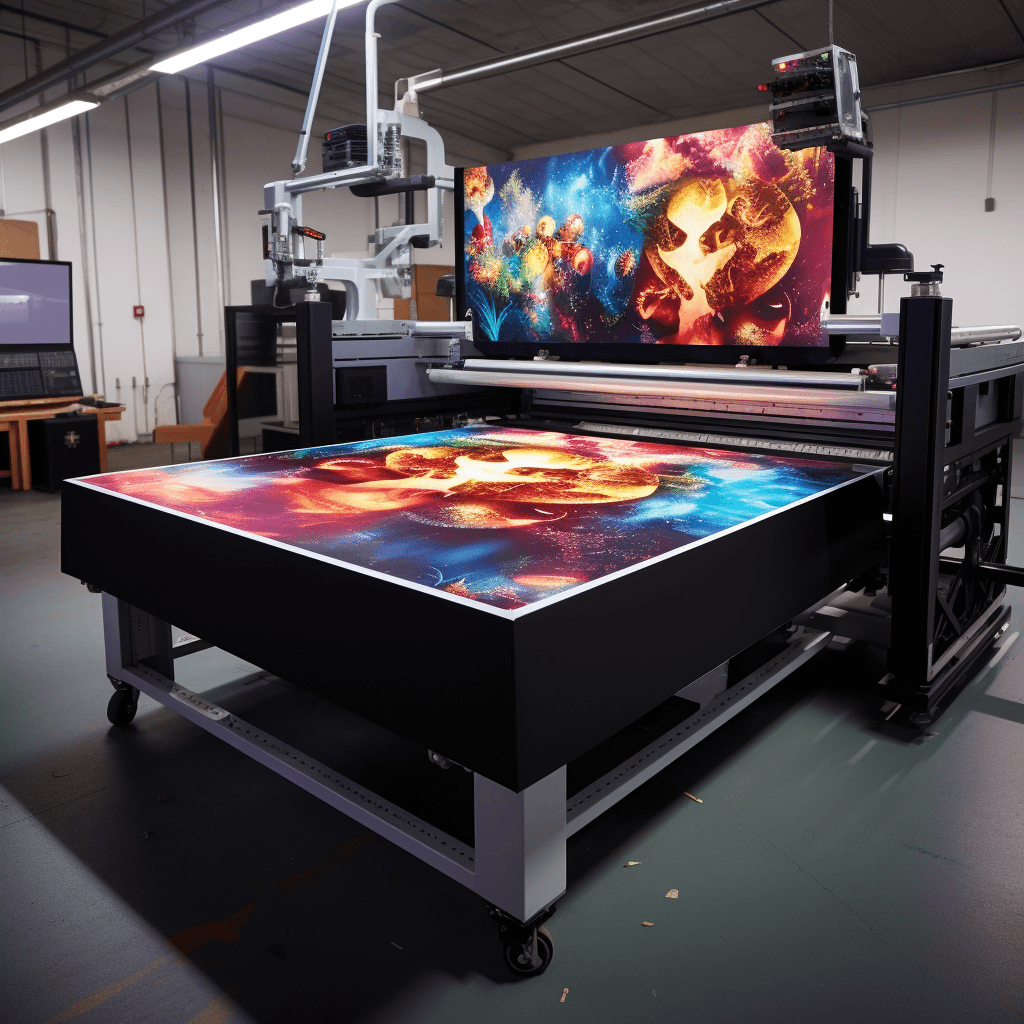

What is Flatbed printing

Flat bed printing is a technique that involves placing a flat, rigid substrate on a printing bed and directly applying the printing process to its surface. This versatile method allows for printing on a wide range of materials including paper, cardboard, wood, glass, metal, plastic, and more.

Flat bed printing employs various printing technologies. Among them is the widely-used UV (ultraviolet) inkjet printing method. In flatbed printing, UV-curable inks are utilized, and these inks are instantly cured or dried through exposure to ultraviolet light. As a result, a diverse range of materials can be printed upon, yielding vivid and long-lasting prints.

Flatbed printing is often employed for large-format printing applications. Including signage, banners, posters, point-of-purchase displays, and other promotional materials. It is also used for printing on rigid materials for applications like packaging, architectural signage, and industrial printing.

Advantages

One of the advantages of flatbed printing is its versatility.Handling different substrates and producing high-quality prints on materials that may be too thick or rigid for other printing methods. Additionally, the UV curing process allows for quick drying and the ability to print on non-absorbent surfaces.

Overall, flatbed printing is a popular choice in the printing industry for various applications where direct printing on flat, rigid substrates is required.

Flatbed printing typically involves the use of inkjet technology. Liquid ink is digitally applied directly onto the substrate to create the desired image or text.

Here’s a simplified overview of the process:

- Preparation: The flat, rigid substrate is prepared and placed on the flatbed of the printing machine.

- Inkjet Printheads: The printing machine is equipped with inkjet printheads that contain tiny nozzles. These nozzles spray small droplets of ink onto the substrate.

- Image Processing: A digital file containing the image or design to be printed is processed by the printing system. This can include color management, scaling, and other adjustments.

- Ink Application: As the substrate moves through the printing machine, the printheads deposit the liquid ink onto its surface. The ink is precisely sprayed onto the substrate, creating the desired image.

- UV Curing (in UV flatbed printing): In UV flatbed printing, the ink used is UV-curable, meaning it hardens or cures almost instantly when exposed to ultraviolet light. UV lamps are positioned near the printheads or on the printing bed. As soon as the ink is applied, it is exposed to UV light, causing it to solidify.

- Final Output: Once the printing and curing process is complete, the finished product emerges from the printer. The result is a high-quality print directly on the flat, rigid substrate.

The use of UV-curable inks and the instant curing process in UV flatbed printing offer several advantages, including the ability to print on a wide range of materials, faster production times, and the creation of durable, vibrant prints. This process is particularly well-suited for large-format printing on various substrates used in applications such as signage, displays, and industrial printing.

what kind of substrates can you use

Flatbed printing is known for its versatility in handling a wide range of substrates. Making it suitable for various applications. The choice of substrate depends on the specific requirements of the printing job. Here are some common substrates that can be used in flatbed printing:

- Paper and Cardboard: Flatbed printers can handle standard paper and cardboard materials, making them suitable for traditional printing applications like posters, banners, and packaging.

- Wood: Flatbed printing can be used to print directly onto wood surfaces, allowing for applications in woodworking, art, and decorative elements.

- Glass: The ability to print on glass makes flatbed printing suitable for applications like creating decorative glass panels, signage, and glass art.

- Metal: Printers can print on various metal surfaces, providing opportunities for industrial applications, signage, and customized metal products.

- Plastic: Different types of plastic materials can be used, expanding the possibilities for applications such as point-of-purchase displays, promotional items, and industrial labels.

- Acrylic: Flatbed printing is often used to print on acrylic sheets, creating visually appealing displays, signage, and decorative pieces.

- Foam Board: Lightweight foam board is commonly used in signage and display applications. Flatbed printing can produce high-quality prints directly on this material.

- Canvas: This printing allows for direct printing onto canvas, making it suitable for fine art reproductions, wall art, and other artistic applications.

- Textiles: Some of these printers are equipped to handle textile printing. Enabling the direct printing of fabric for applications such as customized apparel, soft signage, and interior decor.

- Ceramics: In specialized flatbed printing applications, certain printers can handle ceramics, allowing for the customization of tiles and other ceramic surfaces.

It’s important to note that the capabilities of flatbed printers can vary. Not all large format printers are designed to handle all types of substrates. Additionally, surface preparation and ink compatibility may be considerations when selecting the appropriate substrate for a specific printing job.

Are large sizes possible

Yes, printers are capable of producing large-format prints. One of the advantages of flatbed printing is its scalability, making it suitable for a variety of sizes . Including large formats commonly used in signage, banners, and other promotional materials. The maximum size a flatbed printer can accommodate depends on the specific model and design.

Large-format flatbed printers are commonly used in industries where oversized prints are required, such as:

- Signage: Printers are widely used for printing large signs for outdoor and indoor advertising. This includes billboards, storefront signs, and other promotional signage.

- Banners: Whether for events, trade shows, or outdoor advertising, flatbed printers can produce high-quality prints on large banners.

- Posters: Printing large posters for advertising, promotions, or decorative purposes is another common application of flatbed printing.

- Point-of-Purchase Displays: This printing is used to create eye-catching displays for retail environments, including large promotional displays.

- Wall Graphics: Printing large graphics directly onto walls or other surfaces for decorative or branding purposes.

- Vehicle Wraps: Some of these printers are designed to handle printing on large sheets or rolls of material for creating vehicle wraps.

The scalability of large format printing makes it a versatile choice for various industries requiring high-quality, large-scale prints. It’s important to check the specifications of a specific flatbed printer model to determine its maximum printing size capabilities, as these can vary among different machines.